Address

RTA Rail Tec Arsenal Fahrzeugversuchsanlage GmbH

Paukerwerkstraße 3

1210 Vienna

Austria

Website

RTA Rail Tec Arsenal

Rail Tec Arsenal (RTA) is an internationally active independent research and testing institute for rail and road vehicles, aircraft and technical systems that are exposed to extreme climatic conditions. RTA operates two modern climatic wind tunnels designed to optimise thermal comfort in public transport vehicles and to investigate and improve the availability and safety of systems in sensitive industrial areas.

In Austria, weather and thermal environment simulations are among the strengths of RTA’s Climate Wind Tunnel, the world’s largest rail vehicle research infrastructure. Since 2014 the large climatic wind tunnel can be converted into the world’s largest icing wind tunnel. Especially in the field of 1:1 scaled icing tests RTA gained practical experience by carrying out several customer projects including certification tests on

helicopter air inlets with running engines or mass flow simulation, engineering and certification tests on UAV IPS as well as several research projects in the icing branch over the last years.

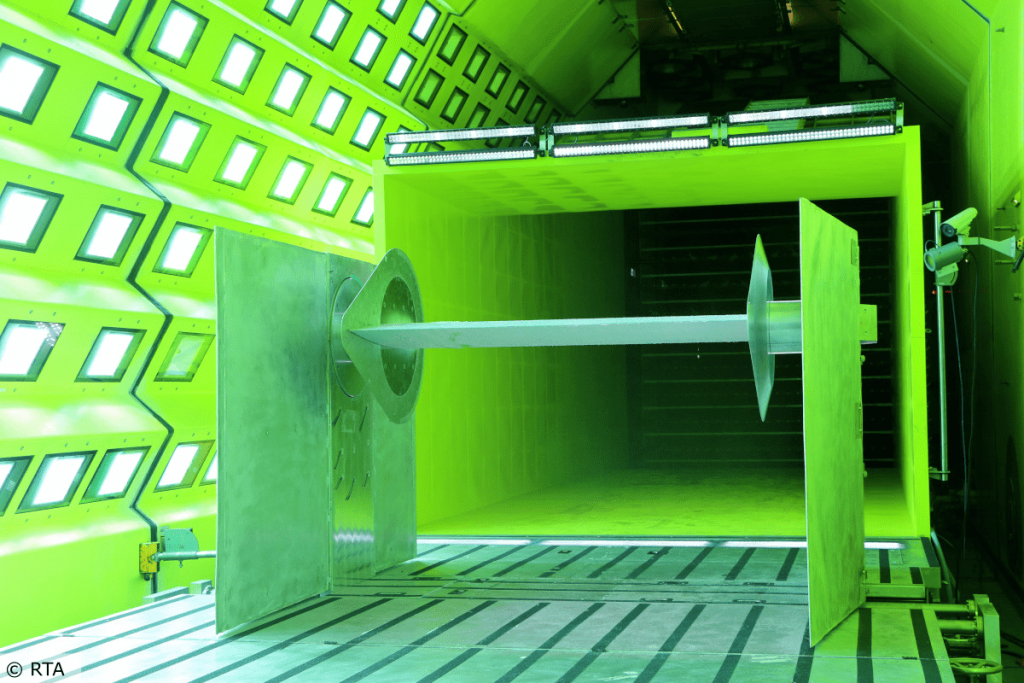

The RTA facility provides an Icing Rig, a high-performance exhaust system and kerosene tank for permanent aircraft fuel supply. By installing the purpose build Icing Rig, the CWT is modified to an Icing Wind Tunnel (IWT) with a cross section of 16.1 m² and airspeeds of up to 20 m/s. With the installation of the additional contraction nozzle, the cross section is reduced to 8.75 m² and enables icing tests at airspeeds of up to 80 m/s. The system is capable of creating SLD clouds as well, which are currently further developed. In 2019 RTA developed a new unique prop- rotor rig for the investigation of

propellers and rotors with diameters of up to 2.5 m under all relevant icing conditions.

The highly qualified RTA staff also offers consulting services for the development of optimal testing scenarios. The technical challenges arising during test planning and testing are resolved in close cooperation with customers. The consistent implementation of customer requests and suggestions allows RTA to continuously improve and enhance its service portfolio.

Role in the project

- Development/improvement of Appendix O process stability / reliability and measurement techniques to be able to measure liquid/ ice water content discrimination.

- Improvement of prop-rotor rig and development of scaling methods inclunding representative ice shedding test procedures development for rotating components. Creating accurate test data with 3D or 4D scans for a validation database who can be provided to code developers or for aerodynamic testing of artificial ice shapes.

- Generated data will be used for certification aspects as well as for development/improvement of numerical simulation tools.